BRAZIL: This month GE Transportation’s factory at Contagem expects to roll-out the first locomotive to completed using a newly-commissioned mixed-model moving assembly line. This is GE Transportation’s first moving production line, and insiders believe it may be one of the first in the locomotive sector.

The plant mainly builds AC44i and ES43BBi locomotives for the Brazilian market. Unlike stationary production lines, the moving line is designed so that employees assemble different locomotive configurations on the same line as hydraulic systems move the locos down the track at speeds between 1·15 and 2·20 m/h. Sensors enable real time remote monitoring of progress, enabling any problems to be addressed.

GE Transportation says this lean manufacturing approach has cut the plant’s lead times by 20%, reduced inventory by US$1·75m and freed 1 256 m2 of floor space. The overall time required to build a locomotive is expected to be reduced from 19 to 15 days, and could be cut further as staff gain experience.

'This new manufacturing approach allows for optimisation of the whole production process and promotes the company’s lean culture', said Contagem’s Industrial Director Afonso Borges. ‘It enables us to improve the entire production system from end-to-end, and from the supplier to the final customer, which contributes to delivering better results, ensuring a more competitive and flexible business.’

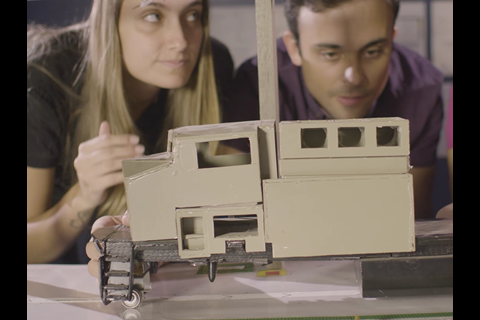

Commissioning of the moving production line follows four years of planning, which included the use of scale models to test the concept and more than 100 simulations to understand factors which can affect the process.