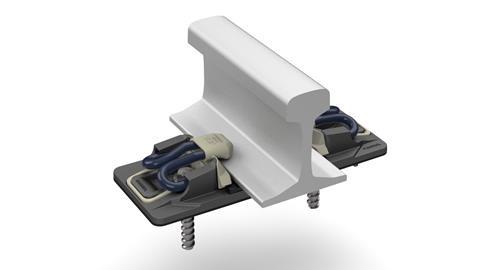

INTERNATIONAL: Pandrol has launched a Common Interface System for ballastless track, so that the fastenings can be adapted quickly and affordably to meet changing performance requirements.

The Common Interface System will accept a variety of different screwed and non-screwed rail fastening assemblies. This would enable a section of track to be altered to meet changing noise and vibration mitigation requirements by simply swapping the fastening assembly, rather than having to modify the whole track structure.

For use in normal environments, Pandrol says the Common Interface System can be fitted with a simple, medium-resilience fastening such as the Fastclip FCA, which provides a system stiffness of 40kN/mm or more.

If the performance requirements increase, the Fastclip FCA can be swapped for Pandrol’s DFC, which has a typical stiffness of 22·5 kN/mm and provides greater protection against ground-borne vibration and secondary noise. Where the highest performance is required, Pandrol’s Vanguard fastening system provides an assembly stiffness as low as 5 kN/mm and a high degree of vibration isolation.

The Common Interface System has been designed for ease of installation and maintenance, enabling a wide range of vertical and lateral adjustments to be made. It also provides full electrical insulation and corrosion protection. The system is also available with low toe load and zero longitudinal restraint configurations for use on bridges and viaducts.

‘At present, rail infrastructure owners have to modify or lift and rebuild non-ballasted track from scratch when performance requirements change’, explained Fastening Systems Technical Director John Porrill. ‘Now, for the first time, they will be able to simply replace the fastening system, resulting in huge financial savings and minimising disruption to our rail network. The Common Interface System is a game-changer, set to futureproof non-ballasted track.’