How advanced material data and finite elements analysis can address prediction challenges of adhesives assemblies.

Prediction of materials and assemblies durability is one of the most challenging tasks of Design Engineers in the Rail industry. Prototyping and accelerated ageings are highly resources-demanding when a reliable statistical analysis of variables is needed, with a large number of samples and testings required. Numerical simulation is a convenient solution for prediction challenges but a predicting model strongly depends on material and assembly data availability and accuracy. When it comes to adhesives assemblies, advanced adhesive properties provide Designers a robust data package to address modelling challenges through complex calculation methods or Finite Elements Analysis.

Approaching adhesive assemblies prediction in a highly standardised Rail industry:

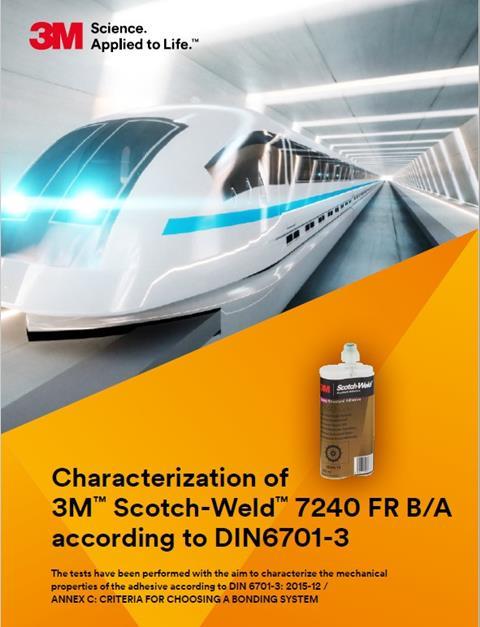

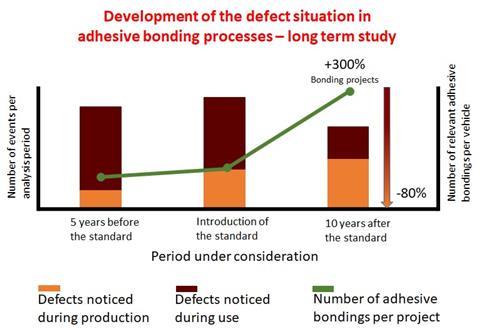

Standardisation of materials and assemblies in Rail industry is at an advanced stage globally, including for instance(1): EN 12633-Structural Requirements of Railway Vehicle Bodies, EN 15227-Crashworthiness Requirements for Railway Vehicle Bodies, EN 45545-2 and NFPA 130 fire standards among others. Considering adhesive assemblies, quality standards such as DIN 6701 Adhesive bonding standard leverage products innovation and define a baseline of performance for bond design and operation, including maintenance. DIN 6701 Part 3 of the standard specifies chemical, mechanical and physical (“CMP”) properties of adhesives for higher safety requirements A1 and A2, and adhesive manufacturers must align products data to these requirements. These adhesives data packages are generally used together with material datacards (“MDC”) for the purpose of Finite Elements Analysis required especially for A1 safety level.

Adhesives characterisation and advanced CMP data:

In the approach of multiple passenger rail interior and exterior applications, 3M has characterised three structural adhesive technologies to meet DIN 6701-3 CMP data requirements for A1 and A2 safety classes.

3M™ Scotch-Weld™ 7240 FR B/A is an epoxy-based structural adhesive containing glass beads for minimum bond line thickness control of large metal surfaces lamination of door, floor and wall panels.

3M™ Scotch-Weld™ DP490 is an epoxy-based toughened structural adhesive with additional flexibility for multi-material, large surface bonding including composites.

3M™ Scotch-Weld™ DP8407NS is a fast-curing acrylic-based structural adhesive with exceptional impact resistance for small joints assembly, brackets and panel to frame bonding when toughness and short-time holding power is required.

Additionally, for lower requirements safety classes such as DIN 6701-3 A3 and Z, new 3M Acrylic structural adhesives formulations with increased flexibility and elasticity 3M DP8610NS and low odor 3M DP8710NS have been developed for applications such as floor panels seam sealing.

Designers can select one or more of these 3M adhesive solutions to develop the bonding project with a DIN 6701 approach for rail components bonding (equivalent to DIN 2304 standard when considering other markets.) and deliver more reliable predictions on assemblies performance with significant reduction of defects in production and service.

Case study: applied numerical simulation of adhesive assemblies using advanced CMP data.

The partnership between 3M and the design company BLUE Engineering s.r.l. in the scope of applied rail numerical analysis, provided in this example a combination of innovation in design, improvement of rail components durability prediction and performance, and alignment with rail bonding standard DIN 6701 with applied finite element analysis.

Bonding technologies have many benefits such as connecting dissimilar materials (e.g. aluminum, composites, steel), simplifying the geometry of the parts, reducing manufacturing time and costs, optimising the structures behaviour and lowering degradation of material mechanical properties caused by thermal and environmental ageing.

The synergies and collaboration between 3M and Blue Engineering allowed to leverage top performant bonding technologies for innovative railway applications prediction: as an example of case study, the two companies worked in a specific project sharing the experience of 3M on bonding technologies and the knowledge of Blue Engineering on railway structure design.

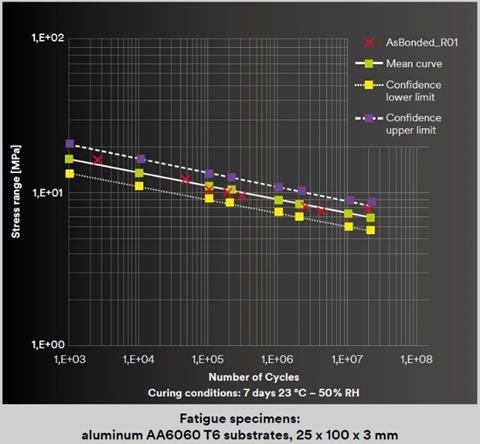

The activity target was to design and optimise the bonded joints of a new EMU (Electrical Multiple Units train) according to the standard DIN 6701. The vehicle has been designed to comply with most requiring Technical Specifications for Interoperability. More in detail, the loads were referred to EN 12663:2010 for inertial forces and UIC660 for the pressure.

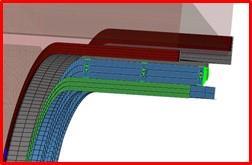

After the preliminary definition of the joints design by Blue Engineering, 3M suggested a candidate adhesive reference 3M Scotch-Weld™ 7240B/A FR and bonding process. The two companies teams worked together performing the joint simulation by using finite elements analysis. 3M shared the material data sheet and data card (MDC), including DIN6701-3 adhesive data package with advanced adhesive properties to simulate the joint behaviour and optimise bond design. 3M Scotch-Weld™ 7240B/A FR DIN6701-3 data package accelerated the design process and modeling. Blue Engineering defined a detailed mathematical model suitable to simulate in detail the bonding performance. This interactive process allows a state-of-the-art technical advisory for application performance prediction.

The main dimensioning parameters in this study were: tensile properties, lap shear stresses and maximum shear strength, bonded joint geometry, temperature and environmental boundary conditions. A value of 95% confidence interval was the limit considered for the fatigue analysis.

The softwares applied by Blue Engineering to perform the design optimisation were: Catia™ V16R6 for the design, Hypermesh for pre and post-processing, and Abaqus™ as FEM solver. A strong advantage of the mathematical model was that 3M shared the material data card directly in the Abaqus™ format, avoiding any misalignment. The mathematical model has been made by hexa8 elements (e.g. about 20.000 for the detailed area).

3M global technical support team and 3M Partners are ready to support Rail Engineers and Designers with answers to questions around adhesive characterisation, modeling and simulation. We have developed state-of-the-art test and simulation capabilities for structural and pressure-sensitive adhesives that allow us to model and predict mechanical performance, damage, thermal behaviour, influence on vibration damping and noise reduction, and many other applications.