UK: A strategy identifying 12 'key capabilities' that the rail sector needs to develop in order to increase capacity and improve customer service in the 'age of the digital train' was published by a group of industry bodies led by standards organisation RSSB on February 7.

Endorsed by the Rail Supply Group and the Rail Delivery Group, the Capability Delivery Plan builds on the Rail Technical Strategy published in 2012 and Network Rail's Technical Strategy from 2013.

The 12 'whole system' key capabilities are:

- Running trains closer together to increase network capacity, supported by the Digital Railway signalling and train control programme;

- Minimising disruption through the use of predictive and preventative maintenance;

- Efficient passenger flow through stations and trains, with smarter ticketing and human-centred design;

- Using real-time data to make better decisions and provide useful and up-to-date information;

- Optimising energy use through intelligent distribution and storage;

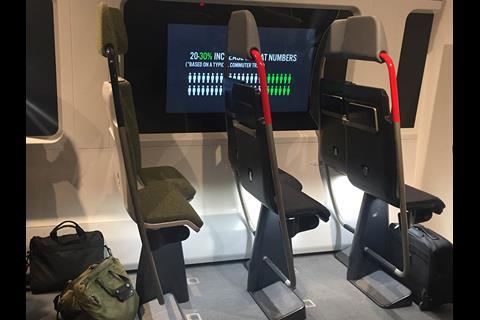

- Train interiors that meet passengers' different and changing demands;

- Knowing the exact location and speed of all trains in real-time to improve situational awareness, increase operational flexibility and enable faster recovery from disruption;

- Intelligent trains knowing where they need to be and when, and able to automatically adjust journeys to meet demand;

- Personalisation to provide passengers with tailored information and services so that rail becomes a seamless part of an overall journey;

- Flexible freight trains designed to carry varying loads combined with better planning and tracking;

- Low-cost infrastructure and trains using light rail and automotive technology to make lightly used lines more viable and make rail a more competitive option for new transport links;

- Creating an environment to support increased R&D investment, and removing barriers to the adoption of technology.

The CDP provides a framework for prioritising development within the supply chain. 'Delivery of these capabilities requires strong leadership, co-ordination, and collaboration from all parts of the industry', said Graham Hopkins, innovation lead for the Rail Supply Group. 'A united effort can ensure that the plan's milestones are included in industry planning, and that funding is co-ordinated, targeted, and secured.'

More than 200 individual research and technology projects are planned. These include a mobile app that could increase throughput by using Bluetooth to open ticket gates without physical contact. This is to be trialled by Chiltern Railways this year. It is envisaged that biometric technology such as fingerprint or iris scanning could in the future allow passengers to be automatically identified and a travel account billed, enabling ticket gates to be removed.

Novel seat designs are to be tested this year with the aim of improving comfort and providing space on trains for up to 30% more people on trains.

'Our railway is increasingly full, and while the industry is taking action to address the challenges of today, we also need to be looking at the solutions of tomorrow', said Rail Delivery Group CEO Paul Plummer. 'This blueprint sets out how we can harness digital technology to make journeys better for passengers and freight customers on a railway that's simpler and easier to use.'