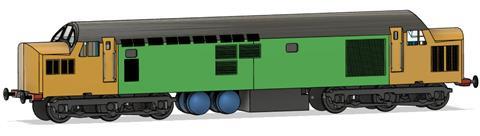

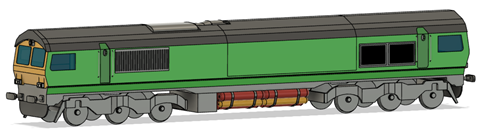

UK: G-volution and SBL-Rail have produced design concepts for dual-fuel versions of Class 37 and 66 locomotives, which would be able to run on diesel with biomethane, biopropane or hydrogen.

The concepts aim to show how engine technology developed for other sectors could be applied to rail. SBL-Rail told Rail Business UK that the conversion of a prototype locomotive could be completed within 24 months of an agreement being reached with a locomotive owner.

The Class 37 is currently powered by an English Electric 12CSVT engine and the Class 66 by an EMD 12-710 engine. Both would be replaced by a new dual fuel engine developed by G-volution and which would meet Stage V emissions standards. A concept for a twin engined Class 59 and Class 66 using a pair of smaller engines has also been developed, as well as a dual fuel ‘evolution’ of the existing EMD engine.

The locomotives’ existing diesel tanks would be replaced by a smaller tank plus cylinders to hold the biomethane, biopropane or hydrogen. A range of tank concepts has been proposed for each fuel, with fewer larger or more smaller cylinders.

Biomethane can be manufactured by anaerobic digestion of organic food, farm and sewage waste as a renewable replacement for natural gas.

Biopropane can be manufactured from biomass or through biological routes as a renewable replacement for liquefied petroleum gas.

Performance has been modelled using data provided by locomotive operators and data from G-volution’s dual fuel combustion research.

For the Class 66, the new four stroke dual fuel engine is predicted to offer a 10% improvement in fuel consumption compared to the original two stroke EMD engine. The dual fuel evolution variant retaining the EMD engine would offer a higher diesel replacement rate, but the two stroke engine would be less efficient than the new four-stroke dual fuel engines and would not meet the latest Stage V emission standards.

The companies said that on an energy equivalent basis and at 2020 prices, biomethane is 0·47 times and biopropane 0·58 times the price of diesel. Hydrogen is currently 1·3 times (using natural gas) to 6 times (using electrolysis) the price of diesel for an equivalent amount of energy, and so the EMD hydrogen dual fuel evolution would cost more to run.

The new dual fuel hydrogen engine options would offer cost savings, primarily because the engines’ improved efficiency over the original prime mover would lower overall operating costs.

Biomethane and biopropane dual fuel engines would offer significant carbon and cost savings verses diesel. Hydrogen has the potential to do so if produced from renewable sources, but would need to be ‘much cheaper’ than it is today.

Whilst diesel prices are expected to rise, biomethane and biopropane are disconnected from the crude oil price and their prices are expected to fall as production volumes continue to ramp up. Green hydrogen made through electrolysis using renewable electricity would requires electricity prices to fall or diesel prices to rise even further for it to offer operating costs savings over diesel.

| Modelled carbon and cost savings | ||

|---|---|---|

| Carbon savings (%) | Operating cost savings (%) | |

| Class 37 - new dual fuel engine | ||

| Diesel-biomethane | 67 | 58 |

| Diesel-biopropane | 64 | 55 |

| Diesel-hydrogen | 66 | 44 |

| Class 66 - new dual fuel engine | ||

| Diesel-biomethane | 51 | 29 |

| Diesel-biopropane | 42 | 21 |

| Diesel-hydrogen | 49 | 7 |

| Class 66 - EMD dual fuel evolution | ||

| Diesel-biomethane | 81 | 39 |

| Diesel-biopropane | 71 | 26 |

| Diesel-hydrogen | 79 | -28 |

| Hydrogen results assume green hydrogen is used | ||