CZECH REPUBLIC: Track component manufacturer DT-Výhybkárna a strojírna has launched a three-year research project aimed at developing an ‘autonomous turnout’ which can monitor its own condition and predict any problems before they can cause a failure.

Emphasising that turnouts are among the most heavily stressed infrastructure components, the Prostějov-based company explained that its ultimate goal was ‘to create a system capable of continuously monitoring the technical condition of railway turnouts’ and indicating the need for maintenance intervention. It believes that such a diagnostic system could be deployed on both conventional and high speed lines, reducing the impact of inspections and maintenance on train operations.

Backed by a grant from the Czech Technology Agency under the country’s Transport 2030 programme, the three-year research project has a budget of around KC20m. It is the second phase of a collaboration that has already seen four years of work with partners including the Brno University of Technology faculties of Civil and Mechanical Engineering and the Jan Perner Faculty of Transport at the University of Pardubice.

Turnouts in the Czech Republic are currently inspected and maintained manually, which either requires a line blockade or ‘red zone’ working with staff on the tracks while the trains are running. The latter is prohibited on routes where trains operate at higher speeds.

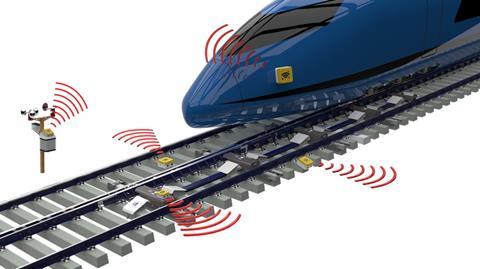

The diagnostic system will use sensors on key turnout components to record vibrations under passing trains, which can then be analysed by intelligent algorithms to identify any changes and flag up ‘undesirable’ conditions that require attention. These could include wear on highly stressed components such as the crossing, deformation or rail surface defects. The evaluation system will also determine the optimum timing for specific interventions, enabling infrastructure managers to plan their maintenance programmes more effectively.

Over the past four years, the partners have been focusing on the monitoring of fixed components, as well as designing a system architecture for data acquisition, transmission and evaluation. The next phase will look at the assessment of moving parts, including switch blades and movable crossings.

‘Our immediate focus is determining the optimal placement of sensors on movable turnout components’, explained Principal Investigator Lukáš Raif when the project was announced on January 20. That would be followed by a trial installation of sensors on selected turnouts across the SŽ network for field testing.

‘This project will save financial resources and reduce the workforce required for infrastructure maintenance’, added DTVS Chief Executive Marek Smolka. ‘Another key benefit is employee safety, as physical inspections conducted during operations today will in the future only occur when the system signals the need for intervention. Autonomous turnouts will help prevent potential failures and unplanned service disruptions, by ensuring the reliability of railway infrastructure and thus improving the reliability of train operations.’