GERMANY: Plasser & Theurer’s presence at the IAF infrastructure construction and maintenance trade fair on May 31-June 2 will be encapsulated by the theme ‘future track technology — NOW’. Among the developments being highlighted in Münster by the Austrian track machine specialist will be the addition of Mauritius as its 110th export market.

Plasser’s display is intended to address a number of sectoral challenges that the company has identified. Noting that a lack of qualified staff has become a major issue in the track maintenance sector, the company believes this is accelerating a trend towards greater automation. Plasser is currently working on various field trials to assess how contractors and infrastructure managers using its machines could best mitigate looming staff shortages.

At IAF, a Unimat 09-8x4/4S BR Dynamic E3 hybrid tamping machine will showcase the automation of maintenance of high-capacity turnouts. Short track possessions make it necessary to maintain switches and crossings in ‘a fast and precise manner’, with integrated ballast management becoming an essential prerequisite, Plasser suggests.

The new machine offers a more spacious and comfortable crew compartment than earlier models, and it is fitted with a single cab for two operators, carried on the main frame. With digital systems supporting the work processes, this should allow maintenance tasks to be undertaken with fewer people.

Ballast, welding, services

Also on display will be a ballast distributing and profiling machine which Plasser says is its first to feature a sweeping unit suitable for use with both concrete and wooden sleepers. The machine’s settings can be switched from one type to the other in a simple process, eliminating the time and effort needed to reconfigure the sweeping unit on earlier machines.

The ballast regulator is designed to be tailored closely to individual customer requirements, and Plasser has introduced a matching simulator to support the flexible and portable training of ballast regulator operators, making it easier for contractors to upgrade to the latest design.

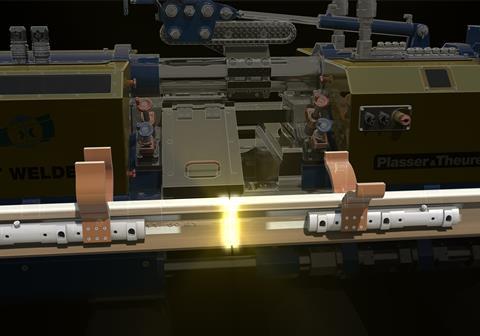

The APT 1500 mobile flash-butt welding robot has been developed to a compact design which enables it to be transported by lorry within standard weight limits. An updated variant is to be unveiled at IAF, featuring a welding head approximately 35% lighter than its predecessor, and a simplified sensor arrangement.

Meanwhile, Plasser will use the exhibition to highlight its growing services business. In July, the company is due to open a European Distribution Centre at its production facilities in Linz, which will allow it to ‘secure the original spare part supply chain for our customers’. The Customer Services business unit will also launch a Used Machines offering, enabling customers to buy second-hand machines directly from the manufacturer.

Plasser and its partners will also be highlighting its Retrofitting service, whereby track machines of different shapes and sizes can be refurbished and updated by installing the latest components and working units. Reflecting the company’s growing emphasis on servicing and aftermarket support, the Linz factory is currently undertaking a four-month long overhaul and modernisation of a 114 m long high-output track renewal train for DB Bahnbau Gruppe.