INNOTRANS: A detailed and location specific passenger information system is one of the highlights of the Series X metro trains which Siemens Mobility is supplying to the Austrian capital’s transport operator Wiener Linien.

In September 2017 Siemens Mobility beat Bombardier Transportation to win a contract to supply 34 six-car trainsets and provide 24 years of maintenance. There are options for a further 11 of the trainsets, which are being manufactured at Siemens Mobility’s Wien plant.

A pre-series train was delivered in 2020, and deliveries are scheduled to the end of 2030.

They are expected to enter service on lines U1 to U4 from this year, replacing older Silberpfeil vehicles, and then from around 2026 they will operate in the future U5, which is being built as Wien’s first fully automatic line.

Design

The styling of the Series X trainsets is intended as a continuation from the design elements of Wiener Linien’s existing fleet while meeting the latest international safety standards.

The aluminium-bodied cars have an open and bright walk-though interior, with a seating layout offering an improved sense of spaciousness and providing step-free access to wheelchair and multi-purpose spaces.

A transparent partition behind the driver’s cab offers passengers ‘a new perspective’ of the line.

The trains are equipped for automatic operation on the future U5 or manual operation on other routes, with the trainsets able to run across most of the city’s metro network.

The control equipment is in a cabinet in the middle of the train, rather than in the cabs, and if lines are converted to automatic operation in the future the cabs could be removed to provide capacity for a further 24 passengers.

Key features include LED lighting, sliding steps at every door, CCTV with live access from the control centre, air-conditioning and regenerative braking, with electrodynamic braking down to a standstill to reduce wear and maintenance costs. TSA supplied the traction motors.

The X Series are the first production trains to use air-free brake-by-wire technology developed by Liebherr and Siemens Mobility. This aims to lower maintenance costs and reduces the time required for train commissioning as well as cycle time by using electric brake controls to eliminate the need for piping and all pneumatic components for controlling the brakes.

Passenger information

The trains are the first to be fitted with the Passenger Info Plus dynamic information system developed by Siemens subsidiary Hacon in co-operation with the operator.

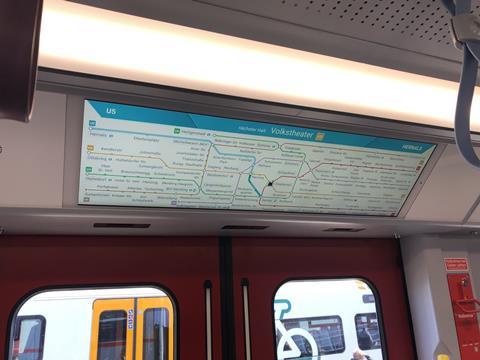

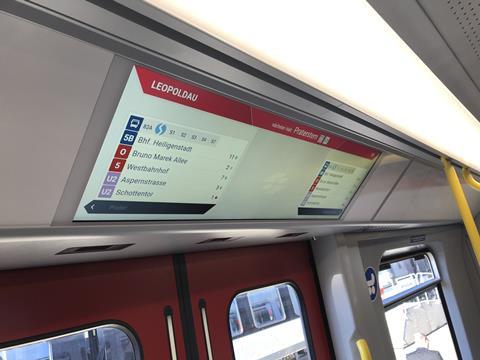

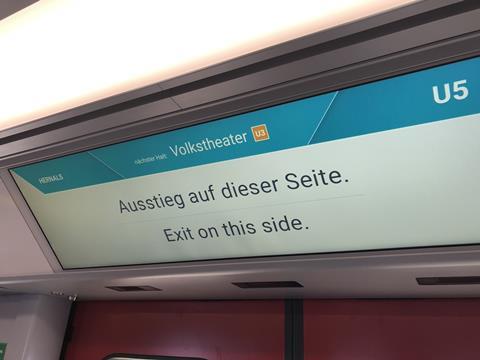

Screens in each car will provide real-time information about the progress of the train and dynamic network data. Displays above the doors show information customised to that door and location, including directions left and right to the station exits and the available transfer options, routes for wheelchair users, and departure times for connecting services.

The doors on the opposite side which do not open at a station will show a digital map of the U-Bahn network, highlighting the train’s current position, direction of travel and next station.

| Siemens Type X trainsets for Wiener Linien | |

|---|---|

|

Length m |

111·25 |

|

Width mm |

2 850 |

|

Floor height above rail mm |

1 000 |

|

Axleload tonnes |

10·90 |

|

Seats |

200 |

|

Passenger capacity (4/m2) |

928 |

|

Maximum speed km/h |

80 |

|

Maximum acceleration m/s2 |

1·2 |

|

Power supply |

750 V DC third rail |

|

Wheel diameter mm |

840 |