The increasing digitalisation and automation of many areas of life is also shaping our approach to mobility and presenting the rail industry with fundamental changes and opportunities.

Digital and automated technologies are not just buzzwords, but active drivers that are redefining the way we perceive and use rail transport. The integration of intelligent technologies opens up a wide range of possibilities for more efficient, safer and more environmentally friendly mobility.

The HÜBNER Group, a leading supplier and important partner in the mobility industry, is actively involved in shaping this digital transformation. With many years of experience and an ongoing commitment to innovation, the company develops customised, high-performance solutions that make the operation of rail vehicles more efficient, flexible and sustainable. At InnoTrans 2024, the HÜBNER Group will present a range of digital product novelties that promote the potential of these trends and further advance digitalisation in rail transport. Managing Director Kai Mentel offers a first glimpse of the highlights that the HÜBNER Group will be presenting at InnoTrans 2024: “Our trade fair concept perfectly reflects what the HÜBNER Group stands for now and in the future: we combine innovative performance with a comprehensive sustainability approach, thus driving forward future-proof rail mobility.”

The HÜBNER AutoCouple system increases efficiency on the rail

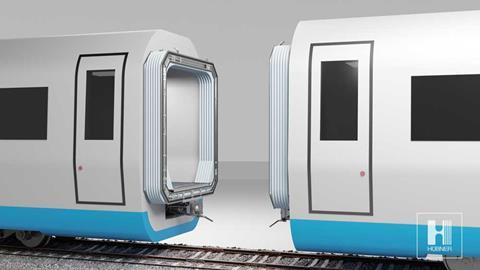

One product innovation currently in development is the HÜBNER AutoCouple System, which is designed to enable fully automatic coupling of gangway systems in the future. The solution is intended for use in passenger trains, especially in metro transport, and can be integrated into new vehicles of most types. It is also possible to retrofit existing passenger transport rolling stock.

With the HÜBNER AutoCouple system, the company aims to open up previously untapped potential for greater efficiency in ongoing operations, while at the same time significantly reducing the time and personnel costs involved in this process. The coupling and uncoupling of wagons in passenger trains is a regular process, with which space capacities have so far mainly been adjusted manually to the current demand. Thanks to the pioneering combination of automation and digital control, the HÜBNER AutoCouple system could mean a significant increase in efficiency for transport operators. It would no longer be necessary to deploy personnel on the track, which in turn increases safety and eliminates the need to disconnect the train from the power supply. Up to 25 minutes could be saved for each coupling process.

Holography transforms passenger information

HÜBNER is also focussing on smart technologies in passenger areas. In cooperation with ZEISS Microoptics, the company is developing a holographic display technology for window systems in trains and buses. This technology - previously only known from science fiction films - enables data like arrival and departure times to be projected directly onto the window panes of vehicles. This ensures greater passenger comfort and at the same time brings further advantages for operators, as Ingolf Cedra, Managing Director of the HÜBNER Group, explains: “Holography offers clear advantages over conventional technologies such as OLED systems. They are more cost-effective, require less energy and space in the vehicle as no complex output media technology is required - all with high image resolution.”

With the holographic displays in window systems, the HÜBNER Group is also utilising the expertise of its youngest business unit, Photonics, for Public Transport. As part of the co-operation, ZEISS Microoptics will use tuneable lasers from HÜBNER Photonics for the production of holographic optical elements, which in turn will be integrated into window systems made by HÜBNER.

The holographic display technology enables information on arrival and departure times as well as local points of interest to be displayed on the windowpanes (Photo: ZEISS Microoptics).

Personalised customer service goes digital

Another significant development at HÜBNER is the expansion of the HUBLink customer portal. It provides customers with additional digital support throughout the entire lifecycle of their products. The goal: HUBLink will allow transport companies to digitally manage the operation and maintenance of their fleet in the most economical and ecological way. They receive targeted information and services for their respective HÜBNER products with optimised user experience thanks to the intuitive and interactive interface. HUBLink makes the Life Cycle Costs (LCC) of a product transparent: transport operators receive specific information on which components and parts that should be replaced during the course of operation and when, and which should be renewed as part of refurbishment. The service also includes up-to-date product documentation, installation instructions, training videos and personalised advice. Genuine spare parts are also available to customers worldwide via HUBLink. With around 30 production facilities and locations in many regions of the world, including the USA, India, China, South America and large parts of Europe, HÜBNER is ideally positioned to serve its international customers with short delivery routes and fast support for maintenance and repairs - on site wherever possible.

HÜBNER Group at InnoTrans 2024

At InnoTrans 2024 in Berlin, the HÜBNER Group will be presenting these and many more pioneering, high-quality systems and components for greater performance and comfort in rail vehicles. This year the focus in Hall 1.2, Booth 120 will be on impulses for more sustainability and energy efficiency in trains. More about the HÜBNER Group exhibit online: https://www.hubner-group.com/en/innotrans