JAPAN: Central Japan Railway has developed a device that allows the shape of wheels to be measured while trains are passing over it at up to 80 km/h.

Following a series of field tests, the equipment is being introduced on JR Central’s Tokyo – Shin Osaka Shinkansen route in the 2025 financial year, ending in March 2026. Similar devices will then be installed for JR Central’s electric rolling stock running on 1 067 mm gauge conventional routes.

The Automatic Wheel Shape Measurement Device is intended to ensure that wheels are reprofiled at the optimal time based on the wear condition of the wheels. Until now reprofiling has been used at regular intervals or after a train has run a specified distance.

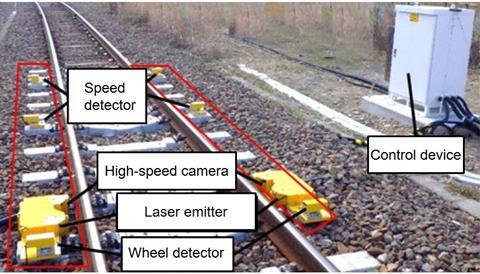

Each device comprises an array of equipment laid in the track. This consists of a speed detector, a high speed camera, a laser emitter and a wheel detector, all of which feed data to a control module located at the lineside. The wheel shape is calculated by projecting laser light on to the wheel and analysing the resulting images.

JR Central describes the equipment as compact, weatherproof and dustproof, noting that the image analysis method is ‘highly accurate’. The company says that in future wheel reprofiling will be carried out at optimal times, ensuring that ride comfort is maintained and improved over the long term.

It notes that the frequency of reprofiling for its electric fleet on the 1 067 mm gauge network is currently ‘high’ and it expects the device will reduce the frequency of reprofiling, extending the lifespan of the wheels and contributing over time to lower costs.