INNOTRANS: Korea Railroad Research Institute is to highlight eight of its latest innovations and research programmes during the upcoming Berlin fair.

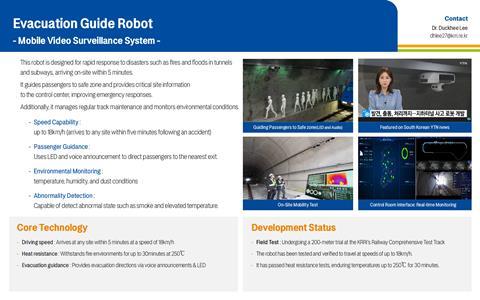

Evacuation robot

KRRI’s Evacuation Guide Robot is designed for rapid response to disasters such as fires and floods in main line and metro tunnels. Mounted on a guide rail adjacent to the track, the robot would arrive on site within 5 min and guide passengers via audio and LED indicators to a safe zone while providing critical site information to the control centre.

It would also be able to supervise track maintenance tasks and monitor environmental conditions such as temperature, humidity and dust as well as detect abnormal factors such as smoke and high temperature.

It has passed tests for operation at up to 18 km/h and withstanding fire temperatures of 250°C for up to 30 min.

The robot is currently undergoing further testing including running over a 200 m guideway at KRRI’s test centre in Osong.

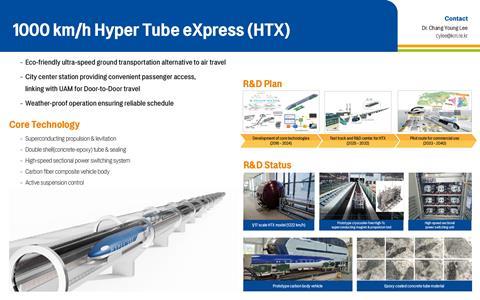

Hyper Tube

KRRI will also be showing its version of low-pressure maglev technology, which it has branded HTX. Targeting operation at 1 000 km/h, Hyper Tube eXpress is designed to be an ultra-speed ground transport alternative to aviation. It would work with superconducting propulsion and levitation in a double-shell concrete-epoxy sealed tube. The vehicles would be constructed using carbon fibre composite bodies.

The technologies have been under development at KRRI since 2016, and a test track and research and development centre are planned to be set up next year ahead of a test programme running until 2032. A pilot route is planned for commercial service from 2033 to 2040.

Rail wear detection tool

KRRI’s Railobse rail profile and wear measurement system uses a non-contact laser sensor that measures rail head condition. The tool then evaluates, analyses visualises and shares the resulting condition data in real-time via an online database.

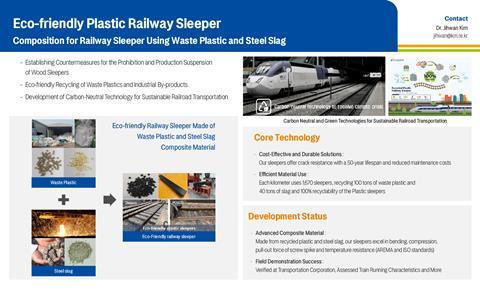

Recycled sleepers

In order to find an eco-friendly alternative to wooden sleepers, KRRI has been working to develop products made of a mixture of waste plastic and steel slag. Typically 1 670 sleepers are needed for 1 km of railway, which requires 100 tonnes of plastic and 40 tonnes of slag.

KRRI claims that the composite sleepers are crack-resistant and have a lifespan of 50 years.

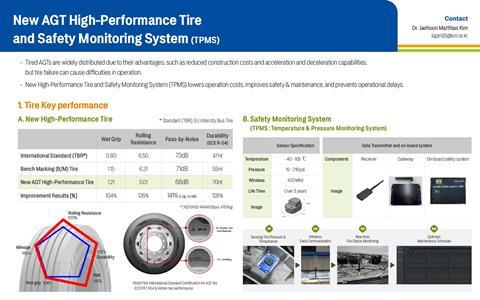

Peoplemover tyre monitoring

In the urban transport segment, KRRI has developed a high-performance tyre temperature and pressure monitoring system for automated guideway transit vehicles.

The equipment is intended to decrease the number of tyre failures and therefore lower operating and maintenance costs of automated peoplemover lines.

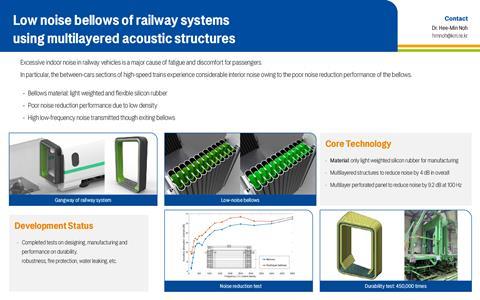

Quiet gangways

Noise-reducing bellows are being developed for inter-car gangways, especially for high speed trainsets. KRRI’s prototypes are made of lightweight and flexible silicon rubber and are manufactured in multilayered perforated panels.

KRRI says it has already completed tests on the bellows’ performance, durability, robustness, fire protection and water ingress risk.

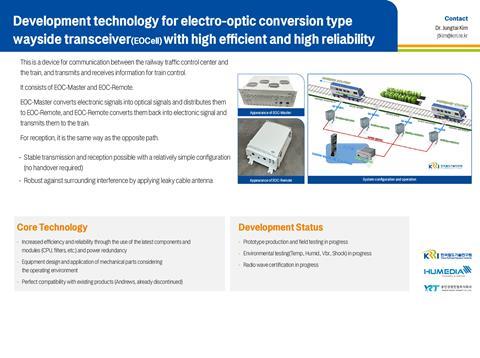

Wayside transponder

KRRI is developing an electrical-optical wayside transponder to better connect control centres with trains.

It transmits train control information by converting electronic data into optical signals and vice versa, the institute says.

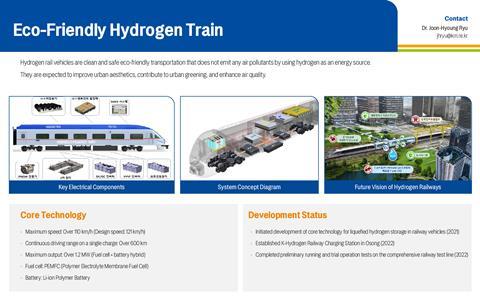

Battery-hydrogen train

The institute continues to refine the design of its hydrogen fuel cell-battery hybrid trainset which it started developing in 2021. The train has a continuous rating of 1·2 MW, a maximum speed of 121 km/h and a range of more than 600 km with one charge. It features a polymer electrolyte membrane fuel cell and a lithium-ion polymer battery.

The trainset completed preliminary test runs at KRRI’s Osong test centre during 2022.